Protective Film for Aluminum Composite Panel

|

Technical Data Sheet |

|

|

Products Name |

Protective Film for Aluminum Composite Panel |

|

Base |

PE |

|

Type of Adhesive |

Water based glue / Solvent based acrylic adhesive |

|

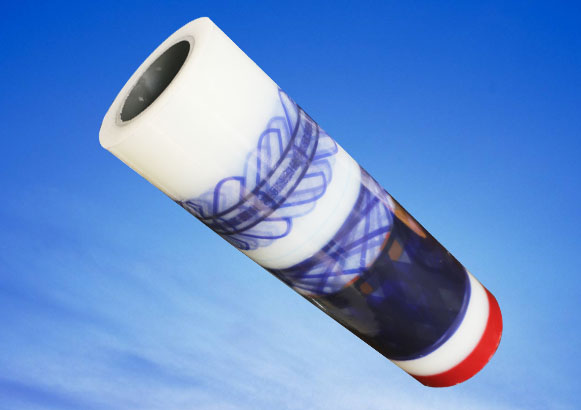

Color |

White, Clear/Transparent, Black, Black&White, Blue, etc. |

|

Thickness (Micron/μ) |

Widely use: 30μ, 50μ, 60μ, 70μ, 80μ, 90μ, etc |

|

Width |

Widely use: 1000mm, 1100mm, 1220mm, 1250mm, 1520mm, etc |

|

Length |

Widely use: 800m, 1000m, 1500m |

|

Printability |

Up to 4 colors |

|

Tensile Strength |

Longitudinally>8N/25mm, Horizontal>15N/25mm |

|

Elongation |

Longitudinally>300% Horizontal>180% |

|

UV Resistance |

Available |

Application :

Protective film for aluminum composite panel,

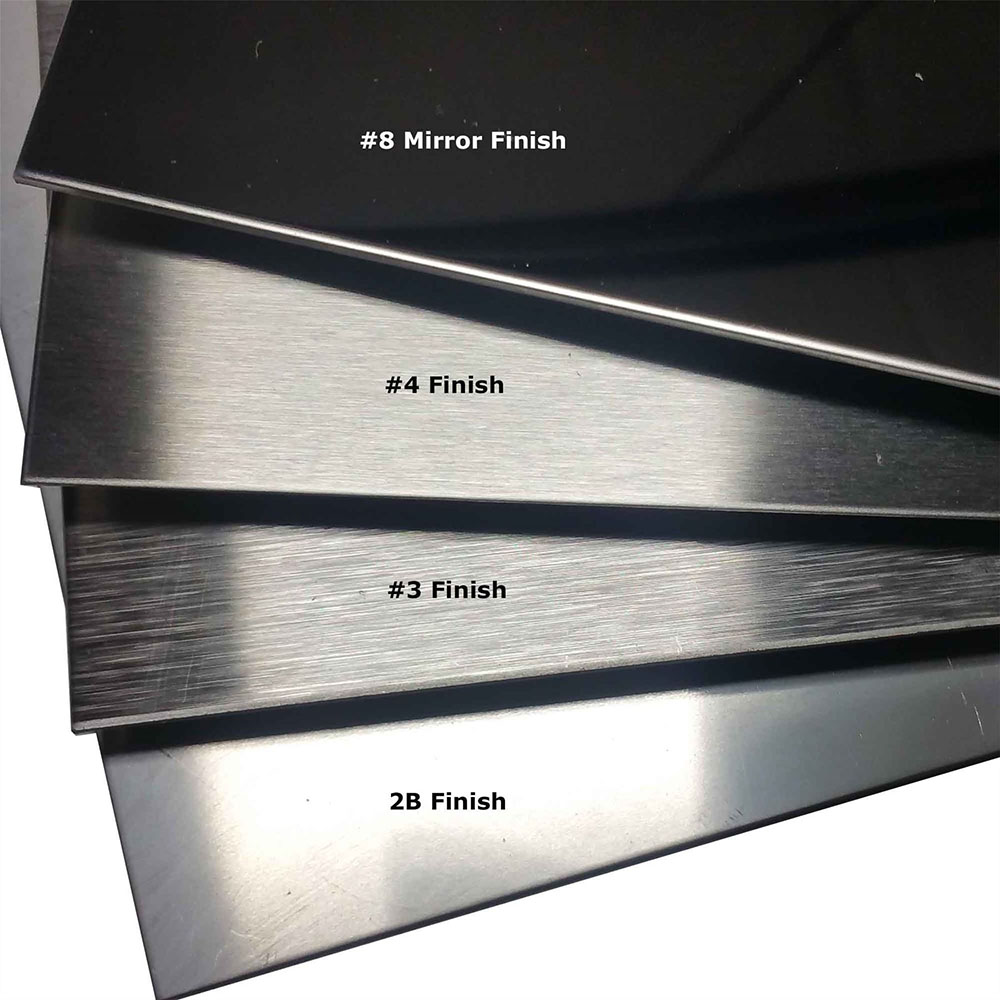

High Glossy Surface,

Glossy Surface,

Matte Surface,

Super Matte Surface,

Perfect products need good protection!

Product advantages:

Zeffer Film prevent damage to surfaces, saving expensive reworking and unnecessary production losses. The protective films not only protect the surfaces of your valuable products during handing, mechanical, transport, assembly, storage process but also can improve your brand image by printing your logo on its surface. We offer films in various quality, color, printability, thickness, length, width and adhesive.

Protective Film For Aluminum Window Profile

Polymer Adhesive Film

Pvc Protective Film

Protective Film for Stainless Steel Plate

Transparent Protective Film

Bule Film

Protective Film for Glass

Self Adhesive Protective Film

Protective Film for Aluminum Composite Panel

Protective Film for Aluminum Composite Panel

Advantages and disadvantages of PVC membrane structure

What are the characteristics of PE protective film

Selection principle of protective film

Advantages of protective film

How to avoid degumming when using the protective film of aluminum plastic plate?

The characteristics and types of protective film

Five main factors affecting hot melt adhesive film

Process comparison of hot melt adhesive film

Definition and characteristics of hot melt adhesive film

Classification of PE protective film viscosit